PRECISION CALIBRATION, STREAMLINED EXPERIENCE

Artel PCS Pipette Calibration System

The Artel PCS, a next generation pipette calibration system, reimagines the calibration workflow for lab technologists. The design of the system provides an accurate, precise, and efficient method for verifying dispensed volumes from any single-channel pipette. The new automated system allows technologists to focus more on pipetting techniques and less on device operation, providing more accurate results. HS Design and Artel collaborated on the design and usability of the system in order to minimize real estate on the lab bench, streamline the calibration process, and provide a new product identity for one of Artel’s premier products.

Featured Case Study

Usability & UX

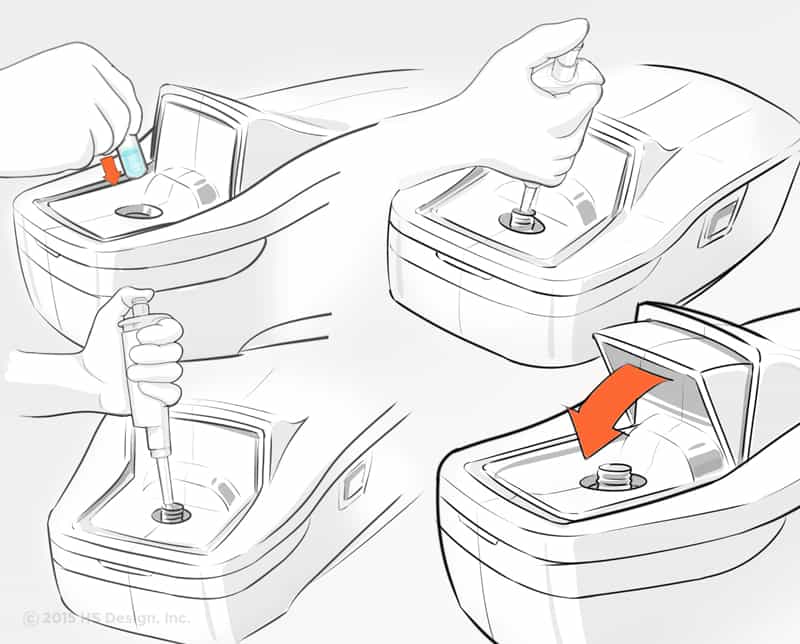

The HSD UX team worked with Artel to streamline the pipette calibration workflow and selected the most efficient and intuitive steps in the calibration process. During the development process, HSD analyzed Artel’s recommended pipette calibration steps and pipetting techniques for dispensing, and designed the system to allow for a more ergonomic operation. Designing the instrument with low shoulders in the front removed obstructions in the path of the pipette, reducing the risk of pipette tip collisions with the instrument and reducing strain on the operator’s arm and shoulders. Foam models of various concepts were created early in the design phase and were tested by current customers to determine how newly implemented features would alter current operations. Feedback from users on the new system was taken into consideration throughout the course of the design and development of the product.

Design

Bench space is often limited in labs, and can be a challenge for lab technologists. HS Design worked with Artel to reconfigure the system architecture of the PCS to ensure the new instrument would be as compact as possible, while improving ergonomics. The PCS was designed to be a mobile instrument that can be moved to the lab in which pipettes are used. A convenient recess was built into the instrument base to allow for ergonomic lifting and carrying. HSD designers and engineers worked together to increase the visibility of the vial while modernizing the form. With its tapering form, strong character lines, and carefully selected colors/finishes, the bold and unique design of the PCS creates a precedent for the look and feel of Artel’s future products.

Engineering

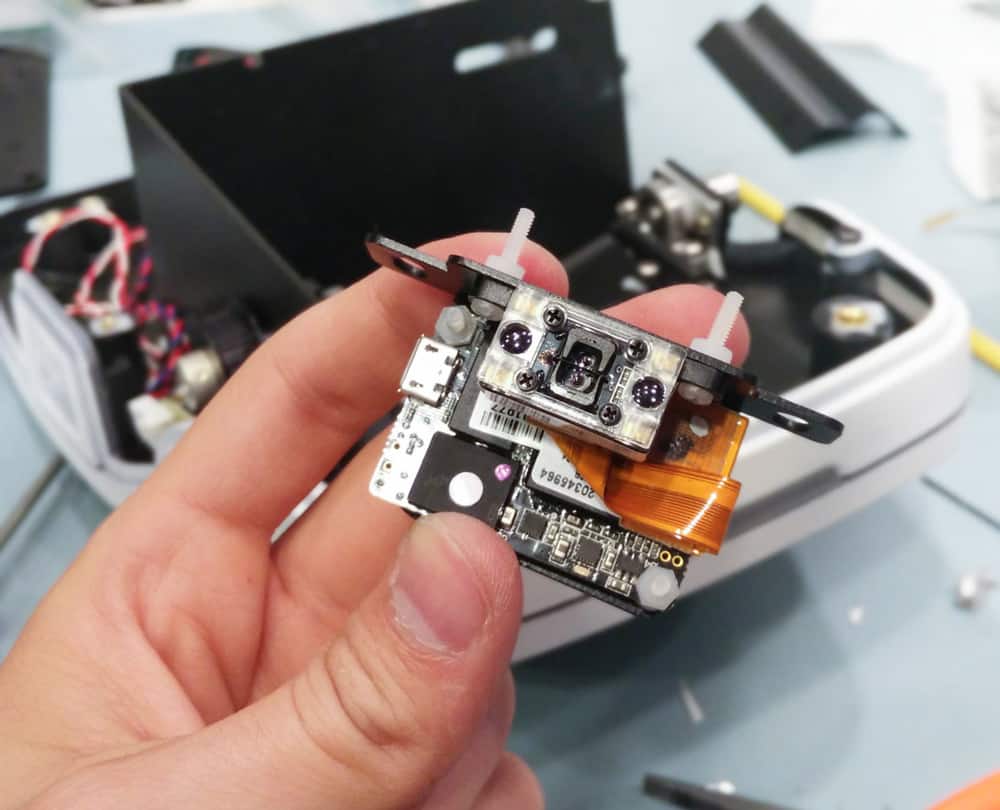

With the end goal of streamlining the calibration process, HS Design incorporated a capacitive touch bar into the system. This replaced the need for manual operation and the possibility of pinching one’s fingers. The protective door, specifically designed to shield the fine tuned ratiometric photometry sensors from light infiltration, utilizes a contoured hood which allows it to retract into the system. Through the use of creative mechanical design, large components such as motors were organized into a compact internal architecture and thermally isolated from the optical measurement components. In order to minimize the bench space occupied by system accessories, a scanner was integrated on the side of the system. The HSD design and engineering teams and Artel worked together throughout the process to ensure the accuracy of the system would not be compromised.

Prototyping

FDM printed parts were used to rapidly test and refine subsystems of the device. While new circuit boards were still in development, HSD’s engineers tested many individual electrical components as a single system through the use of Arduino and LabView. Once the full system was ready for user testing, urethane casts were made prior to tool manufacturing. This allowed HSD to build a system for safety testing with material properties representative of the production unit.