Industrial design as a whole is a wide open and diverse field that touches lives every day in nearly every activity. The big differentiation between industrial design in consumer product development and medical product development are the certification processes and quality. Each of which is super important to how products are brought to commercialization.

There have been some amazing changes in the product development landscape in the last 25 years. Companies like Apple, have changed consumer expectations for each of quality, function, and design. There was a time when anybody could produce a medical, electronic, or consumer product, and the final result wouldn’t have any real differentiation from what was already being used.

Taking a step back to evaluate the landscape just 10 years ago, the medical space was under-appreciated. Tor Alden, Principle of HS Design expresses that, “Design was really driven based on the rugability or having to have a 10+ year obsolescence for medical (product development). Everything was beige in the operating rooms, nobody dared to make any changes to electronics that may go out of trend within the next few years. It was a really different world between medical and consumer product.”

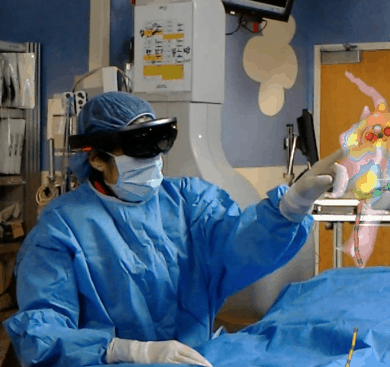

Today, with the evolution of technology, personalized healthcare, and increased patient focus, the medical device design space rivals that of some of the best consumer product designs. Especially in the areas of industrial design and user interface. Tor continued on by stating, “I personally think that the technology has helped increase the obsolescence. Products are becoming obsolete quicker. There’s a much bigger push now to bring the cost for the device down, which brings into consumer product principles.”

The products being used in the medical device space are getting closer to the patients and the patients care more about it today than at any other point in history. The patient has been empowered to give input and expects that their opinion matters. Additionally, the actual users, doctors and nurses, care more about what the product looks like and feels like to them. Healthcare professionals want it to be easy to use so that they have increased efficiency and can provide wonderful patient care. Something that doesn’t operate correctly or feel correct can have a damaging and long-lasting impact on the end results.

That does not mean designing quality and state of the art medical devices is easy.

One of the most difficult challenges to design is documentation. “There were times, 10+ years ago, when a project would be presented to a client after several weeks or months of hard work and was finally coming together. Then the client would walk in the room and just ask, “Well, how did we get here?” Everybody would look around, and people would be trying to validate their answers. They would try to recall each step that they took. This led to taking (documentation) shortcuts to get the product out to prototyping faster. As the process became more sophisticated, missing steps were glaring errors that would shoot down a project in full swing. Design firms would be missing some key decision-making, or if they made a decision, they wouldn’t know how they got there.”

With having a Quality Management System (QMS) process in place, design firms are able to document, not only how they got to a specific step, but more importantly WHY they got there. For example, the Food & Drug Administration (FDA) has guidance documents that outline the proper way to develop a product that’s basically formed by a lot of guidance from AAMI, the Association for the Advancement of Medical Instruments. They’re in charge of writing these documents that the FDA uses for guidance, such as 8075 and 6366.

That being said, the FDA really wants to know more about the front end of the design. How these initial user needs become apparent, how do you develop a product requirement specification, the risk analysis, all these things are done ahead of time prior to really putting pencil to paper.

The best design firms will go to watch a surgical procedure in a contextual inquiry mode where they’re basically being a fly on the wall, watching the surgeons and the nurses collaborate together. Specifically, they are watching how the teams work with a product and where the activity may meet pitfalls. As they are there, they’re also looking to see where the opportunities are, where can insights be collected and then bring them back to the drawing board to solve these unique concerns.

Once those insights are collected, the design team can basically create concepts and system architectures, workflows that will solve those problems that were witnessed.

For the very best design firms, they will even go one step further than that and bring back to the doctors and nurses the updated prototype for what HS Design of New Jersey calls, “formative evaluations” and “formative tests.” Alden states, “We will bring these concepts to them, maybe in prototype forms, maybe in a wireframe, depending on the sophistication of the product. It may be a picture, and if it’s simple enough, we’ll have prototypes for them to hold and talk through. We’ll actually get their insight on which is their preferred, and we do that in a quantitative method where we’ll have an actual ranking and result of the preferences.”

The added benefit of going into such depth is that this process also gets through the full documentation process that the FDA likes to see. Having done such heavy lifting as the process is underway when the approved product goes into market or production and the final validation called the summative test is administered, the product will be brought to those users which participated on the front end, as well as new users using it for the first time. The users will be watched in use, making sure that they can operate the new product. The Summative Test will grade whether the product has a training curve or whether it has instructions for use, but the goal is to have the users maneuver the product inherently on their own, without use error. To Tor Alden, “…that really is the differentiation in a nutshell between medical product development and a consumer, for example. If a consumer product fails, the user might get frustrated. In a medical product, the user might die.”